The Wilson Audio Acoustic Diode

The Process

The Wilson Audio Special Applications Engineering® (WASAE) Team has always approached the challenge of vibration mitigation from a scientific perspective. Once the science surrounding the elements to be deployed is acutely understood, the art of the project can begin.

While designing the Pedestal®, a very effective tool used under audio equipment, the objective of this device was to isolate the equipment chassis from vibrations entering the gear from the surface it’s installed on.

Wilson Audio has successfully employed extremely precise laser vibrometer testing equipment for well over a decade and a variety of other analysis systems previous to these tools. Valuable data collected from this equipment during dozens of product development cycles, including the R&D of Pedestal, gave the WASAE Team greater insights into the complexities of vibration management under loudspeakers. Putting to use their industry-leading understanding and material measurement database, the team set the lofty goal of improving upon an element of the loudspeaker that traditionally has been very good for Wilson Audio.

The Mechanics

Loudspeakers interact with their environment in two primary ways. First, with pressure originating from the driver’s diaphragm and second, the vibrations directed into the floor from the enclosure through the speaker’s footers, or “spikes.” The first is what audiophiles and music lovers hope to experience in its most powerful, engagingly elegant, and intimately emotion ways when their system is turned on. The second is the area of exploration, and the primary focus, of this amazingly functional Acoustic Diode system.

An improved spike system would have to minimize vibration from the enclosure going into the ground while simultaneously diminishing unwanted vibrations from be transmitted up into the enclosure. We have seen and scrutinized many ways the interface of loudspeakers to the floor are addressed. Many companies simply develop spikes to isolate the loudspeaker from the floor. These methods with elastomeric materials, ceramic bearings, and a wide variety of other designs can allow the loudspeaker to move in parallel with the drivers. Unfortunately, these micro-movements can sonically present themselves as smearing, colorations, and various forms of distortion during musical playback. These artifacts can add an effect to the music that may be initially interesting and possibly exciting. The reality, however, is the fidelity of the recording has been altered.

To remedy this, direct coupling to the floor is needed while, at the same time, not providing an easy path for vibrations to be injected into the ground.

The Science

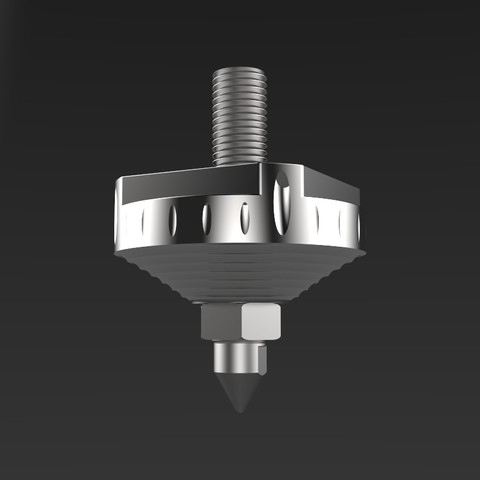

Building upon the research and development of Pedestal, the Special Applications Engineering Team is excited to announce the Wilson Audio Acoustic DiodeTM (AD Spike for short). At the heart of the Acoustic Diode is our proprietary “V-Material.” This superior constrained layer damping composite is unsurpassed in vibration absorption and resonance control.

Energy from the enclosure migrates into the V-Material where it is faced with the effective damping properties of this efficient material. The mass of the loudspeaker concentrated onto the very small ends of the spike tips results in significant levels of PSI that prevent detrimental vibrations from traveling upward into the footer. Those vibrations that do travel up the spike are absorbed by the mass of the Acoustic Diode and have to travel through the V-Material to have a chance to influence the enclosure. Keeping the spike and threaded post separate prevent a direct path for vibrations to travel, or interplay, and are therefore dissipated and absorbed in either the V-Material or the footer housing.

This distinctive design, combined with advanced vibration-mitigating materials, provides the best of both worlds; a solid base from which the drivers can launch as well as preventing the transmission of energy from the floor to the loudspeakers.

Separation in the Assembly

A machined V-Material insert is inset into the robust austenitic stainless-steel diode housing. A stainless-steel post is then threaded into this exclusive V-Material, never touching the diode component. On the bottom of the diode, a spike is threaded into the diode housing, but it does not couple with the V-Material insert. Once the Acoustic Diodes are installed into the loudspeaker, only the V-Material section of the diode comes in contact with the bottom of the loudspeaker.

Comments